About Us

Scinus Cell Expansion brings the SCINUS bioreactor NG to the market, providing a cost-effective solution for the cultivation of clinical relevant numbers of cells in the field of Cell Therapy and Regenerative Medicine.

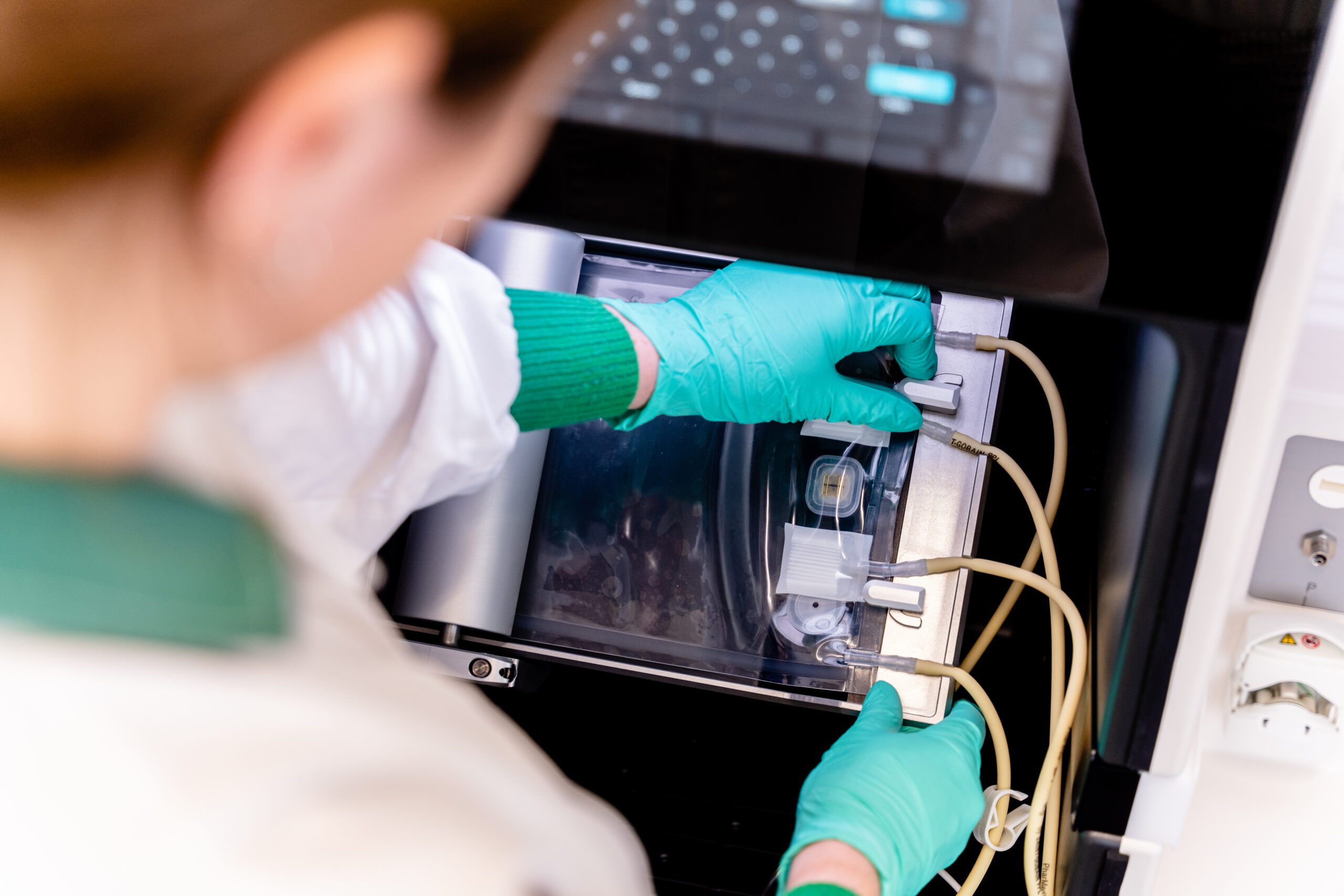

Scinus Cell Expansion provides technologies and process development to enable and improve cell therapy and regenerative medicine. Our main product is the SCINUS bioreactor NG, which is a closed bioreactor system for the controlled cultivation of cells, supporting R&D as well as GMP processes.

Combined with either the single-use Adherent or Suspension Bag it provides a scalable system for large-fold expansion. The temperature-controlled hardware enclosure houses the Single-use Bags on a unique, volume-expandable, rocking platform that provides an optimally homogenized culture environment with minimal shear stresses.

Two different single use bioreactor bags can be used to either cultivate adherent cell types (e.g. human mesenchymal stromal cells), as well as suspension cell types (e.g. T-cells) to clinically relevant numbers. Both bags can be used with the same Scinus Cell Expansion system configuration.

The company was founded by Prof. dr. Joost de Bruijn and was awarded funding by the Dutch government (SenterNovem, ministry of Economic Affairs) to develop an automated, closed bioreactor. As a result, a first prototype was built in 2009 that lay the groundwork for automation of the cell culture process. This prototype contained important functional aspects of the hardware cabinet; temperature control, monitoring and control units and a first version of the Single-use bioreactor Bag. Further development was done with the help of funding by the European Union under its seventh framework programme (REACH, project no. 601869).

Collaborating with different end-users (e.g. Leiden University Medical Center), a fully functional third-generation prototype was finalized in 2016. This prototype was able to support high-fold cell expansion through its (patented) unique expansion mechanism, combined with (patented) control mechanisms for the cell culture environment.

Concurrent with the technical development, biological process development was initiated for large-scale culture of bone marrow-derived mesenchymal stromal cells (bMSCs), an important cell type used in multiple cell therapy applications. Partly funded through the European Union’s sixth and seventh framework programme (Stem Expand, project no. 222989; Stellar, project no. 305436), we worked on growing bMSCs on microcarriers to high cell numbers, to support the requirements for cell therapies.

Growth of bMSCs on microcarriers enabled the cultivation of up to 2 billion cells. After the success with bMSC cultivation, the process development activities have shifted to other cell types, including adipose-derived stem cells, muscle precursor cells (MUSIC, EU project no. 731377) and induced pluripotent stem cells. The third-generation hardware was redesigned according to Good Manufacturing Practice (GMP) requirements. In 2018 DEMCON invested in Scinus Cell Expansion Netherlands B.V. to support further market expansion, intensifying the relationship with different KOLs in the field and expand the distribution network.

In 2019 the first GMP compliant SCINUS systems, as well as the SCINUS culture bag Adherent were realized. In 2020 the first R&D SCINUS culture bags Suspension were manufactured and functionally tested. Process development activities have taken place on different types of Suspension cells (e.g. NS-1 cells, Jurkat Cells, T-cells).

Please contact us to learn more about our automated cell expansion solution and how it can help you in manufacturing your cell culture products